Introduction

Plastic materials have become an integral part of our daily lives, finding applications in packaging, construction, automotive, and electronics. A critical property to consider when working with plastics is their melting temperature. Understanding this temperature is vital for assessing processing capabilities and suitability for specific applications. In this article, we will delve into Megaplast’s expertise in the melting temperature ranges of various plastic materials commonly used across industries.

What is the melting point of plastic?

The melting point of plastic is the temperature at which a solid plastic material transitions from its solid state to a liquid state. At this temperature, the intermolecular forces holding the plastic’s polymer chains together weaken, allowing them to move more freely. This softening process eventually transforms the plastic into a liquid form.

The specific melting point varies based on the type and composition of the plastic material. Different plastics have different chemical structures and properties, resulting in varying melting points. For instance, some plastics have relatively low melting points, averaging around 70°C (158°F), while others have higher melting points, reaching temperatures of over 200°C (392°F).

Plastics like polyethylene (PE) with lower melting points typically range from 105°C to 135°C (221°F to 275°F), while high-melting-point plastics like polycarbonate (PC) reach temperatures of 220°C to 250°C (428°F to 482°F). The specific melting point is influenced by factors such as molecular weight, crystallinity, and additives present in the plastic.

The melting point of plastic is crucial for determining the temperature at which plastic can be processed, shaped, and molded. Manufacturers can utilize techniques like injection molding, extrusion, or blow molding by heating the plastic to or above its melting point, resulting in desired shapes and products.

Moreover, the melting point is essential for ensuring the stability and performance of plastic products. Exceeding the melting point can lead to degradation, deformation, and loss of desired physical properties. Conversely, insufficient heating during processing may result in inadequate flowability for molding or shaping.

In conclusion, the melting point of plastic is a critical factor for working with plastic materials, allowing proper handling, processing, and utilization in various industries.

Why is the melting temperature of plastic so important?

The melting temperature of plastic holds significant importance in various aspects of plastic materials during manufacturing and processing. Understanding this temperature is crucial for determining suitable methods of shaping and molding, such as injection molding, extrusion, and blow molding. It also plays a vital role in preventing degradation, deformation, and undesirable changes in the plastic’s properties that can occur when the melting temperature is exceeded.

In manufacturing and processing, the melting temperature of plastic guides the selection of appropriate techniques. Different plastics have distinct melting points, and heating them to the specific melting temperature enables the plastic to transition from a solid to a molten state, facilitating shaping and molding.

Exceeding the melting temperature can lead to several negative consequences. It may cause degradation of the plastic material, breaking molecular bonds within the polymer chains and resulting in a decrease in strength, loss of desired properties, and the generation of unwanted by-products.

Moreover, surpassing the melting temperature can lead to deformation, causing warping, distortion, or loss of shape during processing, resulting in products that do not meet desired specifications. Undesirable changes in properties, such as density, viscosity, or chemical reactivity, may compromise the performance and quality of the final product.

Controlling and adhering to the recommended melting temperature range is crucial for preventing these issues and ensuring the stability and quality of plastic products. The melting temperature serves as a guide for achieving desired properties, dimensional accuracy, and structural integrity during manufacturing and processing of plastic materials.

In summary, the melting temperature of plastic is crucial in manufacturing and processing, guiding suitable methods for shaping and molding, and ensuring overall quality and performance of plastic materials.

Temperature Ranges for Different Plastic Materials

As previously mentioned, different types of plastic materials have different chemical structures and mechanical properties, resulting in varying ideal temperature ranges or melting points. Some frequently asked questions at Megaplast include “What is the melting point of PVC plastic?”, “What is the temperature range of ABS plastic?” or “What is the maximum temperature that PS plastic can withstand?”. In the following section, Megaplast provides a detailed information sheet, including temperature ranges, melting points, and basic features and applications of some popular plastic materials in the current market.

| Material | Temperature Range | Melting Point | Characteristics |

|---|---|---|---|

| Polyethylene (PE) | -50°C to 80°C | 115°C to 135°C | Flexible, durable, chemical resistant |

| Polypropylene (PP) | 0°C to 120°C | 130°C to 171°C | High resistance to heat, chemical resistance, lightweight |

| Polyvinyl Chloride (PVC) | -10°C to 60°C | 100°C to 260°C (depends on the type) | Flame resistance, electrical insulation, rigid or flexible depending on additives. |

| Polystyrene (PS) | -20°C to 70°C | 210°C to 240°C | Transparent or opaque, lightweight, easily molded. |

| Polyethylene Terephthalate (PET) | -40°C to 70°C | 250°C to 260°C | Transparent, highly durable |

| Acrylonitrile Butadiene Styrene (ABS) | -20°C to 80°C | 210°C to 270°C | Excellent impact resistance, rigid and tough, easily molded. |

| Polycarbonate (PC) | -135°C to 135°C | 220°C to 230°C | Light, durable, good light transmission, easily molded. |

About Megaplast Company

M-Color | Color Masterbatch

Color masterbatch is a popular coloring method capable of creating uniform color effects for plastic products. At Megaplast, we provide an extensive selection of color masterbatch products available in an array of vibrant colors. These products can also be tailored to meet the specific requirements of individual customers.

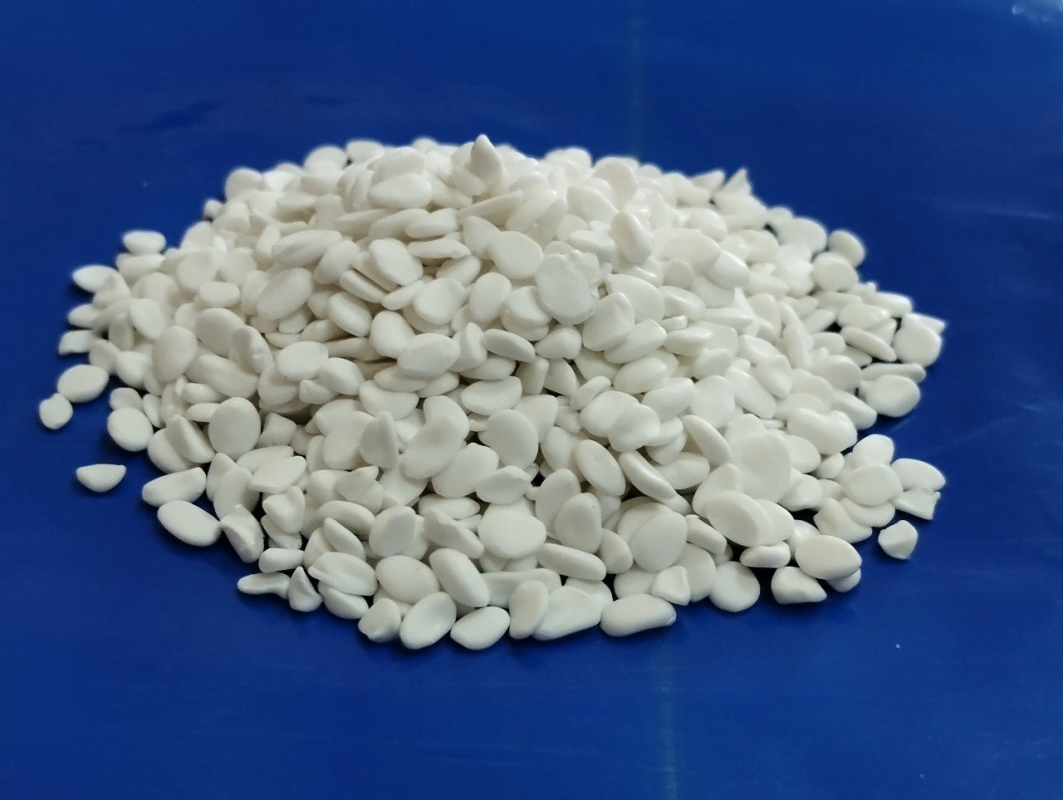

M-Cal | Calcium Filler Masterbatch

The Filler Masterbatch of Megaplast is a combination of PE, PP, or HIPS resin, calcium carbonate (CaCO3), wax, oil, and other additives. The utilization of Filler Masterbatch enables customers to reduce production costs, increase the mechanical properties and dimensional stability of plastic materials, and at the same time achieve the goal of reducing weight. This profit optimization process can be done without affecting the quality of the final product.

M-Tech | Technical Masterbatch

Mega Plast Jsc., offers high quality technical Masterbatch products including PS Masterbatch, GPPS Masterbatch, Talc Masterbatch, etc. Through many years of experience, we are able to provide customized Masterbatch to fit your needs. and help reduce production costs for customers.

At Megaplast, we place great importance on delivering exceptional plastic products that are created with meticulous attention to detail and precise craftsmanship. Our team consists of dedicated professionals with high levels of expertise, committed to providing excellent customer service to guarantee your complete satisfaction.

Contact us today to discover our wide range of products and find the ideal plastic solution that is customized to meet your specific requirements.