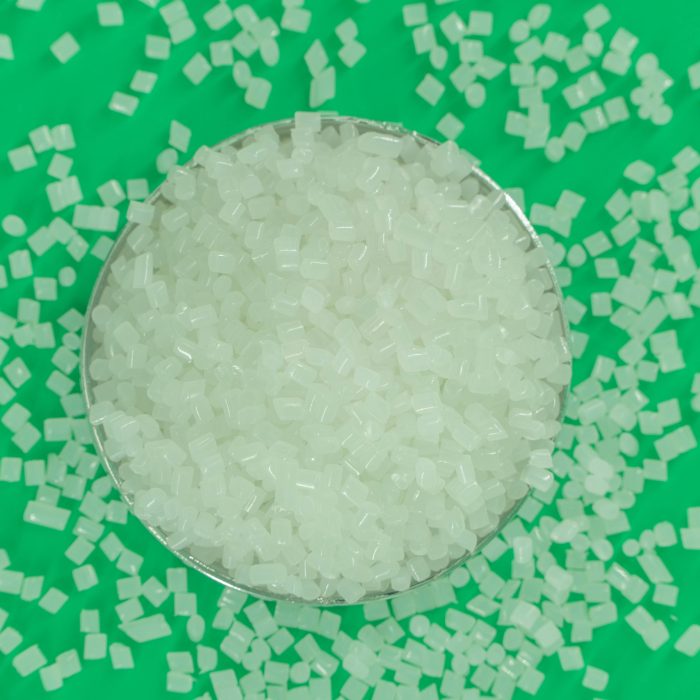

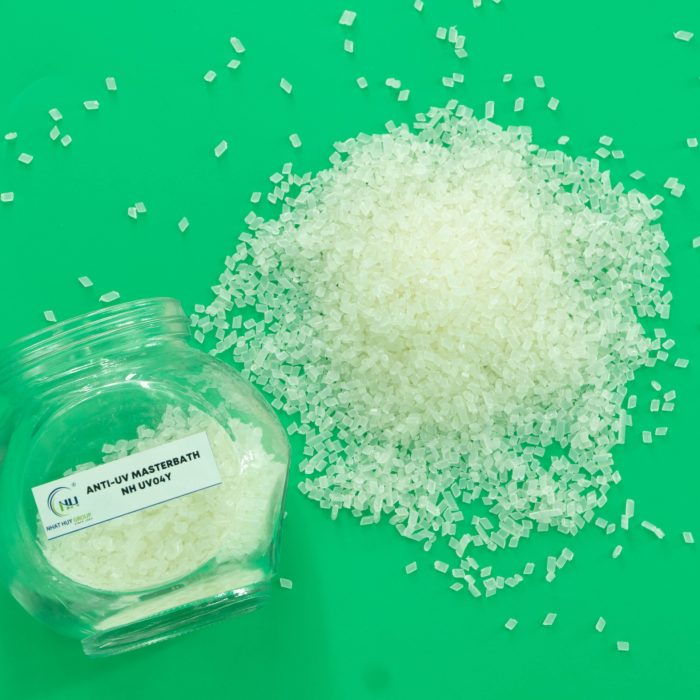

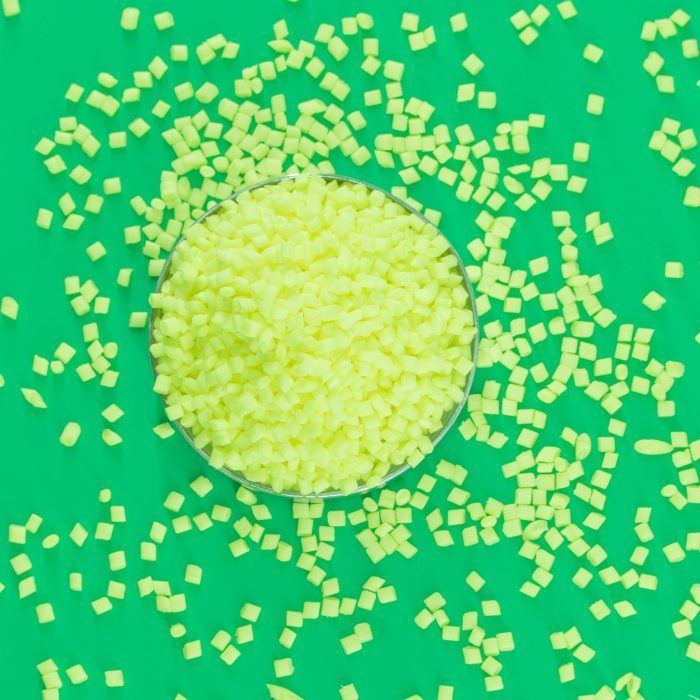

Additives Masterbatch is a mixture of chemical additives in granular form used in the plastic manufacturing process. These granules contain a concentrated amount of additives, allowing them to be easily blended into virgin plastic during manufacturing. Additives Masterbatch is designed to provide or enhance specific properties of plastic products, such as durability, resistance to environmental factors, coloration, and many other features.

Additives Masterbatch enables plastic manufacturers to quickly and efficiently integrate performance enhancements such as heat resistance, UV protection, abrasion resistance, and increased flexibility in the final product. These granules also help in imparting color and aesthetic effects to plastic products, while meeting the strict technical and legal requirements of various industries. Additives Masterbatch also benefits the plastic manufacturing process by reducing cycle times and increasing efficiency. Additionally, it promotes environmental protection by utilizing recycled or biodegradable additives, further supporting sustainability in the plastics industry.

To meet the diverse needs of the market and enhance competitiveness, Megaplast aims to become a leading manufacturer in the masterbatch industry. We are uniquely positioned with our own production facilities for both CaCO3 powder and CaCO3 Filler Masterbatch. Our customers already recognize that CaCO3 filler is an inexpensive component that helps reduce material costs by replacing part of the virgin plastic in the final product. However, Additives Masterbatch offers more specialized solutions to improve product quality, including enhancing durability, UV resistance, heat resistance, and other properties of plastic products.

With the mission to become a leading masterbatch manufacturer, we continually innovate our products by producing various types of masterbatch. Megaplast can meet the specific needs of customers across various industries, from packaging to consumer goods, while maintaining production flexibility and optimizing economic efficiency