During the operation, the engineering team is constantly researching and coming up with innovative initiatives to suit many practical applications and different customers.

The factory has also invested in upgrading the automation of many stages, thoroughly applying 4.0 technology in coordination and production to increase product quality stability.

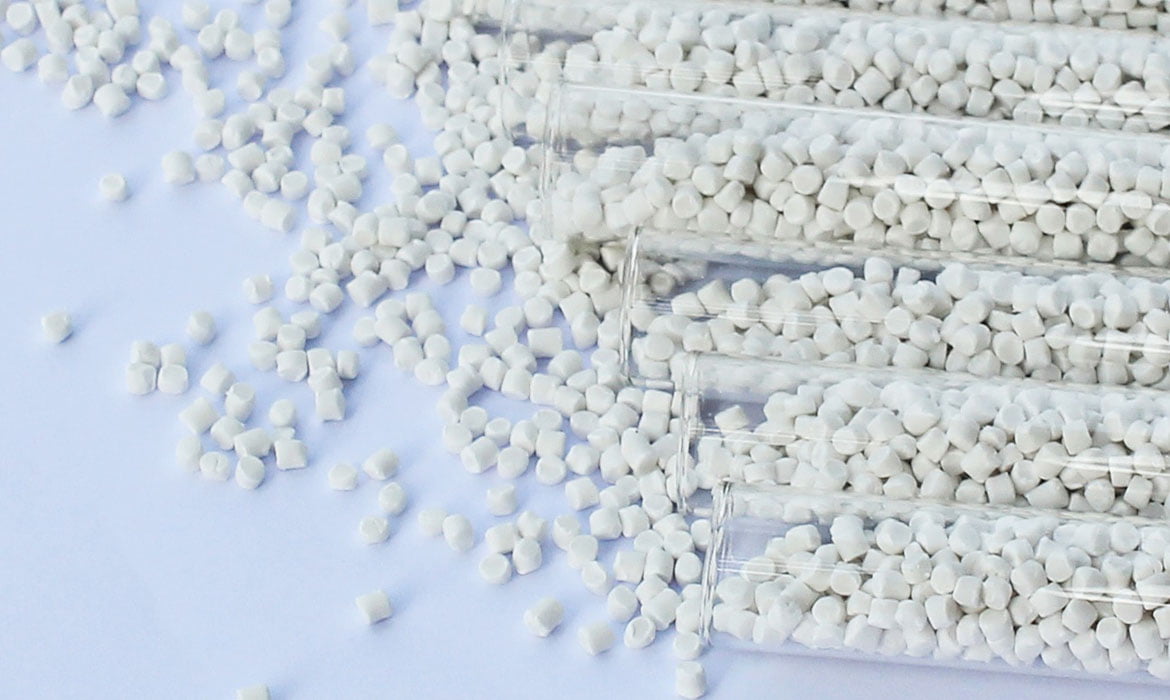

Therefore, Mega Plast’s filler masterbatch product has always won high praise from customer partners, conquering many difficult markets.

Our products are manufactured on modern technological lines including PE with a stone powder ratio > 85% and Max stone powder 8µ, Single PP and PE products with a stone powder ratio <84%, and PP and PE with a stone powder ratio of <84%. high rate of stone powder > 85%.