Table of Contents

I. THE PROBLEM: The Core Conflict of “Cost vs. Quality”

Optimizing costs without losing quality is tough. This case study explores how a custom PP Filler Masterbatch for injection molding helped a client save 15%.

Their business strategy depended on achieving two goals at the same time:

- Produce “good quality products”

- Maintain a “competitive price.”

This created a core technical conflict.

In the injection molding industry, the primary method for cutting costs is using a High loading rate of CaCO3 Filler Masterbatch. However, this solution has a well-known technical problem: when you increase the loading rate, you typically degrade the product. The final items often become brittle, lose durability, and, critically, suffer from a dull, matte surface finish, which reduces their perceived value.

II. The Technical “Trap”

This client’s challenge was far more severe than the general problem. They were in a complete technical trap.

The problem was not just failing to increase the loading rate; they were failing to achieve their quality standards even at a low rate.

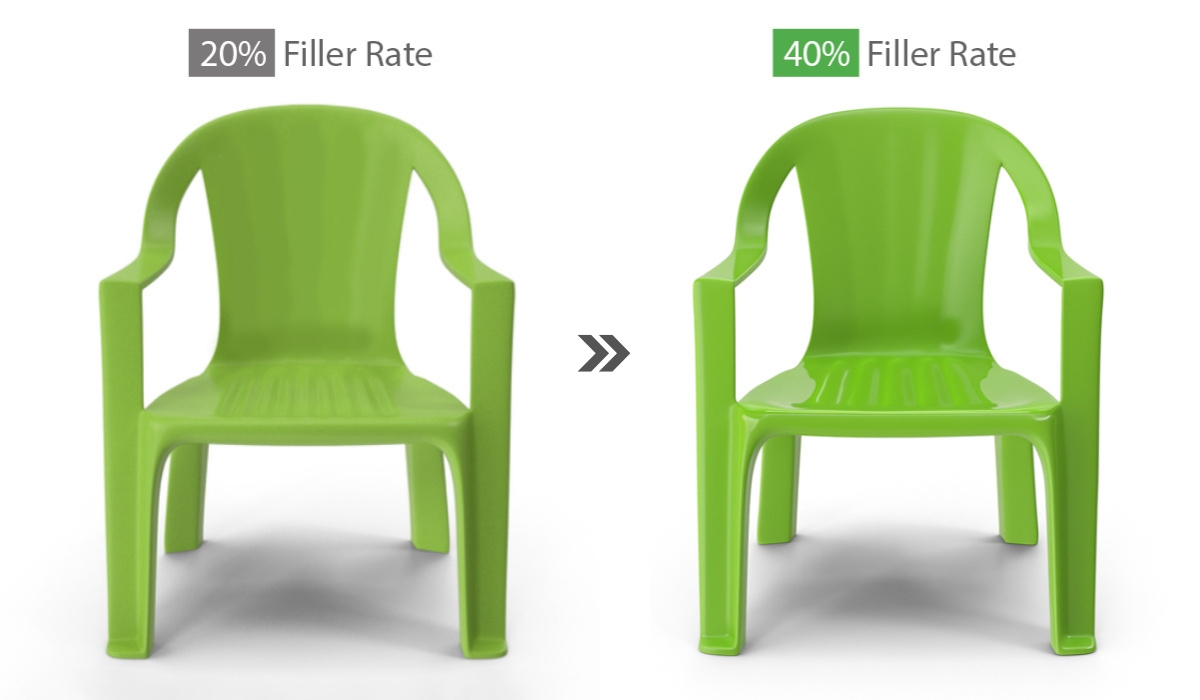

- The “Failure” Data: Data from our tests showed that even when using a standard grade at a low 20% loading rate, the final product still suffered from poor gloss

- The Market Problem: This was a systemic, market-wide issue since the report from other suppliers had the same problem”

This created a business deadlock: They could not increase the loading rate to save money (to 30% or 40%), because it would further destroy the product’s gloss. However they could also not stay at the current 20% rate, because the quality was already unacceptable.

They needed an R&D solution, not just a standard commodity product.

III. THE SOLUTION: A Customized PP Filler Masterbatch for Injection Molding Formula

At Mega Plast, we don’t just supply products; we engineer solutions. Acting as a global technical partner, we launched an intensive two-week R&D project to develop a high-performance PP Filler Masterbatch for Injection Molding exclusive to this project.

The Technical Breakthrough: The secret lay in formulation agility. Mega Plast engineered a new grade by recalibrating the stone powder ratio and infusing high-performance gloss additives. This allowed us to deliver a PP Filler Masterbatch for Injection Molding that solved the ‘dull surface’ trap, proving that high quality and high loading can coexist.

IV. PROVEN SUCCESS: High Gloss Achieved at Maximum Loading

The new, customized PP Filler Masterbatch grade was a complete success, delivering wins on all three strategic goals: Technical, Operational, and Financial.

| Metric | Result | Business Impact |

| Technical (Loading) | Doubled loading rate from 20% to 40%. | Achieved the client’s primary technical goal while also improving the final product gloss. |

| Technical (Quality) | Improved product gloss and achieved Injection: Increase Stiffness. | The final product was visually superior and structurally sound. |

| Operational (Efficiency) | Production efficiency increased by 10%. | The new formula ran smoothly, optimizing the client’s production line. |

| Financial (Cost) | Achieved an extra 15% cost saving. | This provided a significant competitive advantage and a powerful Cost-Saving Solution. |

The client’s feedback was direct: “Good grade, good formula optimization, increased loading.”

Discover The Journey of Filler Masterbatch at Mega Plast

Optimize your PP Injection costs.

Want to achieve 40% loading like this client? Send us your current sample for a free technical analysis and discover your potential savings today