Table of Contents

CaCO3 Filler Masterbatch is at the center of every procurement discussion in the competitive world of plastics manufacturing. Every decision is scrutinized, and when comparing suppliers, price is often the most prominent, decisive factor on the spreadsheet. It feels like a straightforward way to control costs.

But what if we told you that the lowest price on paper could be operating a “hidden factory” inside your plant?

This isn’t a factory with walls or machinery. It’s an invisible facility powered by inefficiency, and it manufactures only three things: waste, downtime, and risk. Every time a decision is made based solely on the upfront price of masterbatch, the doors to this hidden factory swing wide open. It’s time to look beyond the invoice and calculate the Total Cost of Ownership (TCO).

The Raw Materials of the Hidden Factory

Let’s break down the real, tangible costs that a low-quality filler masterbatch feeds into your production line.

1. The Cost of Waste: More Than Just Scrap

- Higher Let-Down Ratios: To save costs, cheaper fillers may use lower-grade calcium carbonate or poor-quality polymer carriers. The result? Poor dispersion, forcing you to use a higher percentage of masterbatch to achieve the desired properties. The initial saving per kilo is quickly erased when you have to use and buy more.

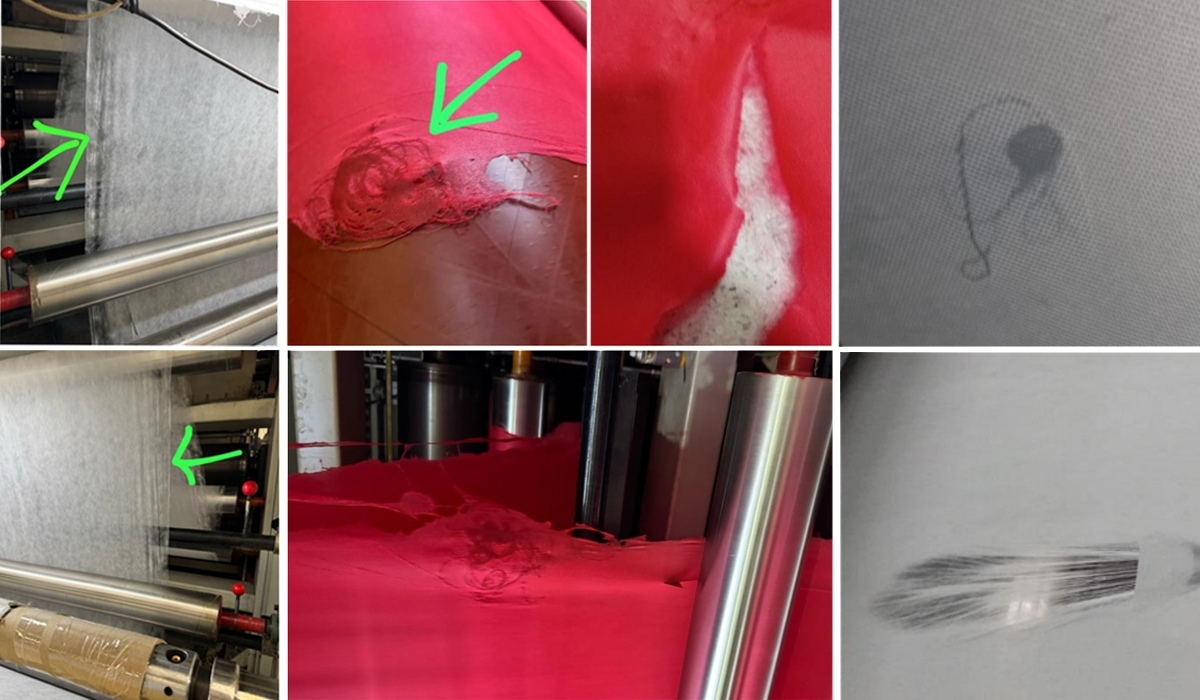

- Increased Scrap Rates: Poor dispersion is the root cause of countless defects. In PP woven sacks, it leads to yarn breakage, creating lines and weak points in the fabric. In film applications, it results in gels and fisheyes, rendering entire rolls useless. Each scrapped product isn’t just wasted masterbatch; it’s wasted virgin resin, energy, and labor.

2. The Cost of Downtime: The Silent Margin Killer

- Frequent Production Halts: In high-speed woven tape lines, “tape-line breaking” is a costly headache. A primary cause is agglomerates (undispersed particles) from low-quality filler, which act as breaking points under tension. Every stop to re-thread the line is a direct loss of output and revenue.

- Abrasive Wear on Equipment: Low-quality fillers often contain abrasive impurities. These particles act like sandpaper on the inside of your expensive extruders, causing premature wear on screws and barrels. The cost of replacing this equipment far outweighs any initial savings on material.

- Increased Maintenance: The dust generated by poor-quality fillers can clog filters and contaminate machinery, leading to more frequent and costly maintenance cycles.

3. The Cost of Risk: The Price You Can’t Afford

- Inconsistent Product Performance: Your customers expect every product to perform to the same standard. When your filler masterbatch varies from batch to batch, so does your product’s tensile strength, impact resistance, and appearance. This inconsistency puts customer relationships at risk.

- Brand Reputation Damage: A jumbo bag that fails under load or a non-woven fabric that feels harsh to the touch directly impacts your brand’s reputation for quality. In a global market, reputation is your most valuable asset, and it’s the most difficult to repair once damaged.

The Cost Calculation: Exposing the “Hidden Factory” with Numbers

Let’s consider a real-world example at a PP woven sack factory with a production output of 1,000 tons of finished goods per month. They are considering two filler masterbatch suppliers.

| Metric | Supplier A (Low Price) | Supplier B (High Quality) | Notes |

| Price | $900 / ton | $950 / ton | Supplier A is $50/ton cheaper. |

| Let-Down Ratio | 20% | 15% | Due to poor dispersion, more of Supplier A’s product is needed. |

| Scrap Rate | 3% | 0.5% | Supplier A’s product causes more yarn breakage, creating scrap. |

| Machine Downtime/Month | 10 hours | 2 hours | Frequent yarn breaks require machine stops for re-threading. |

Assume the production cost (resin, electricity, labor) is $1,500/ton and the cost of one hour of downtime is $200.

Actual Cost Analysis:

- Direct Material Cost:

- Supplier A: 1,000 tons x 20% LDR x $900/ton = $180,000

- Supplier B: 1,000 tons x 15% LDR x $950/ton = $142,500

- Analysis: In terms of required material volume alone, Supplier B already saves the company $37,500 per month, despite having a higher price per ton.

- Costs from the “Hidden Factory”:

- Cost of Scrap:

- Supplier A: 1,000 tons x 3% x $1,500/ton = $45,000

- Supplier B: 1,000 tons x 0.5% x $1,500/ton = $7,500

- Cost of Downtime:

- Supplier A: 10 hours x $200/hour = $2,000

- Supplier B: 2 hours x $200/hour = $400

- Cost of Scrap:

Total Cost Conclusion:

- Total Cost with Supplier A: $180,000 (material) + $45,000 (scrap) + $2,000 (downtime) = $227,000

- Total Cost with Supplier B: $142,500 (material) + $7,500 (scrap) + $400 (downtime) = $150,400

The decision to choose the cheaper supplier on paper is actually costing the company an extra $76,600 every month. That is the operating cost of your “hidden factory.”

Shutting Down the Hidden Factory: The Solution from Mega Plast’s CaCO3 Filler Masterbatch

Understanding these challenges, Mega Plast – one of the leading filler masterbatch manufacturers and exporters from Vietnam – doesn’t just sell a product. We provide a solution engineered to shut down your hidden factory.

The foundation of our products is our CaCO3 Filler Masterbatch, which is made from the highest-quality, whitest limestone sources in Vietnam. But premium raw materials are just the beginning. The difference lies in how we engineer our products:

- Precision Engineering: We utilize advanced technology and machinery to ensure CaCO3 particles are processed to an ultra-fine, uniform size. This allows for perfect dispersion into the polymer matrix, eliminating the agglomerates that are the primary cause of yarn breakage and product defects.

- Application-Specific Formulation: Our CaCO3 Filler Masterbatch portfolio is optimized for specific applications:

- For PP Woven & Jumbo Bags: Special formulations enhance the tensile strength and toughness of the yarn, minimizing dust and virtually eliminating tape-line breaking, allowing your lines to run at higher, more stable speeds.

- For Non-Woven Fabric: Excellent dispersion ensures a smooth, soft fabric surface free of defects, ideal for high-demand hygiene and medical applications.

- For Film & Injection Molding: Guarantees stable clarity, gloss, and mechanical properties, ensuring your final product always meets the highest quality standards.

- A Commitment to Consistency: With a rigorous quality control system, we guarantee that every pellet, in every bag, from every batch, performs with absolute consistency. This brings stability and predictability to your production process.

Choosing a masterbatch should not be a simple procurement exercise; it must be a strategic engineering investment. Investing in a low-price product is funding your hidden factory. Investing in a solution from Mega Plast is an investment in efficiency, stability, and sustainable profitability.

Explore Inside the Mega Plast Factory: Where Cutting-Edge Technology Meets Strict Quality Control

At K 2025, Mega Plast invites you to do more than just talk about products. Let’s analyze your Total Cost of Ownership and co-create a Masterbatch Blueprint that eliminates your hidden factory costs for good. Visit us at Hall 7, Level 2, Booth B25.

Book a consultant schedule now