Table of Contents

CaCO3 Filler Masterbatch for Nonwoven is a strategic choice in India’s highly competitive nonwoven market. For manufacturers, there is strong pressure to lower raw material costs. In this difficult market, the price of filler masterbatch is often the main reason for a decision. But is the lowest purchase price really the best strategy?

Experienced leaders know that the initial price is only part of the total cost. The hidden costs of lower-quality filler masterbatch – like production stops, faster equipment damage, and high reject rates – are quietly reducing profits. This article looks deeper than just the price per kilo. We will show you how choosing the right raw materials can lower your Total Cost of Ownership (TCO), increase your output, and give you a long-term advantage.

The Problem with “Low Prices”: The Real Cost of Low-Quality Filler Masterbatch

Focusing only on the initial cost can be a trap. Local materials may seem cheap, but if their quality is not consistent, they cause many operational problems that cost a lot of money. These problems are common in many factories:

- Filter Clogging and Yarn Breaking: This is a very common problem. Uneven and large CaCO3 Powder particles cause filter blocks (no gridlock) and yarn breaks (No Tape Breaking). Every time this happens, it means the machine stops, wasting time and money.

- Faster Equipment Damage: Rough, impure raw materials damage your machine parts, like the extruder screw. This leads to more expensive maintenance and replacements, and your equipment will not last as long.

- Too Much Dust: Low-quality fillers often create a lot of dust (No Dust). This makes the work area dirty and can affect the final product’s quality.

- Unstable Product Quality: These problems lead to a final product that is not consistent. Bumps, black spots, and weak fabric result in a high number of rejected products. This wastes materials and hurts your company’s name.

A Better Solution: The Benefit of High-Quality CaCO3 Powder

At Mega Plast, we fix the problem from the beginning: the quality of the CaCO3 Powder. Our main advantage is our closed-loop supply chain. We get our high-quality CaCO3 Powder directly from Global Minerals, which is part of our parent company, Nhat Huy Group. This gives us excellent quality control and ensures every batch is the same. This delivers:

- Great Whiteness and Brightness >98.5% for a cleaner, brighter final product.

- Consistent Quality you can trust, order after order.

Discover high-quality CaCO3 Powder at Global Minerals here

The secret to our better performance is not just the source, but our careful and precise process. We use an advanced milling process to make a special material for demanding applications: 10-micron Top Cut CaCO3 Powder.

A Technical Look: Why “Top Cut” Makes a Big Difference

To understand why our filler masterbatch is better, it is very important to understand a key technical detail.

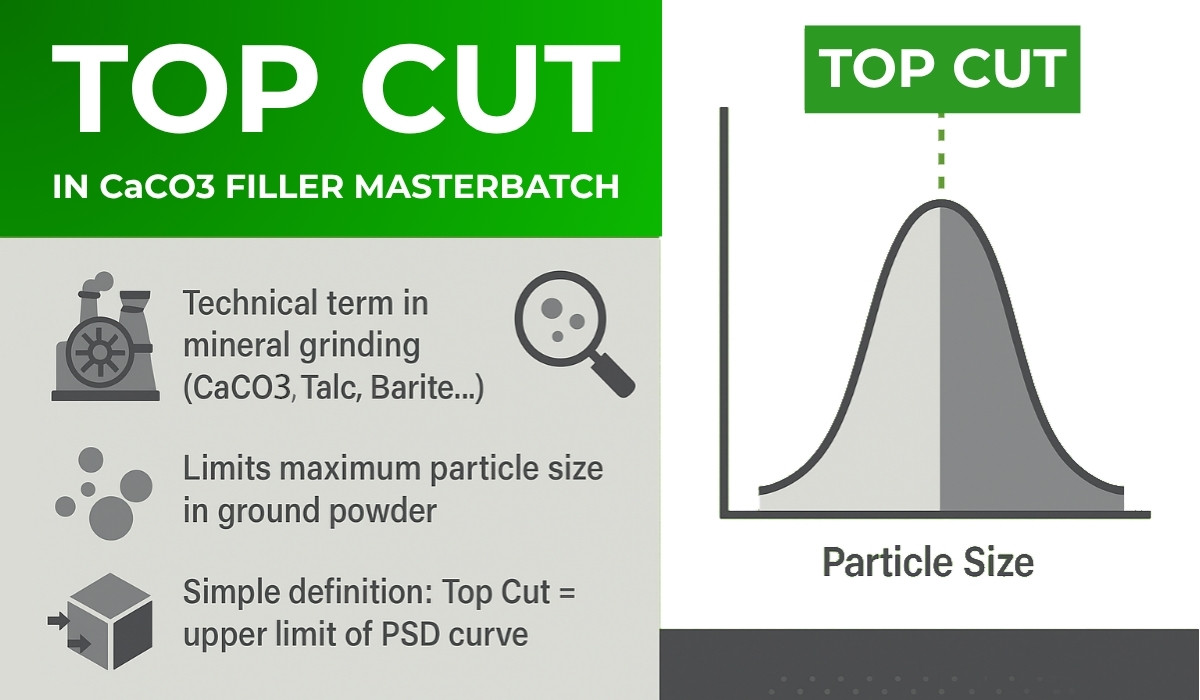

What is “Top Cut”?

“Top Cut” is not a marketing word; it is a very important technical specification in the mineral milling industry. It refers to the maximum particle size limit in the powder. Many suppliers only talk about the average particle size (D50), but this can hide the fact that there are larger particles that cause problems.

A 10-micron Top Cut specification means we control our process to make sure almost no particles are larger than 10 µm. This exact particle size control is the main difference between a standard filler and a high-performance one.

The Impact of 10-micron Top Cut CaCO3 Powder

This level of control has a direct, positive impact on your production:

- Production Efficiency: Large particles are the enemy of smooth production. By removing them, we help your machines run at High Machine Speed. The risk of filter blocking is much lower, and the smooth particles reduce damage to your extruder screws, leading to stable, non-stop operation.

- Mechanical Properties: When particles are the same size, they mix better with the plastic. This creates a nonwoven fabric with high tensile strength, meeting the needs of high-quality products.

- Surface Quality: Fine, controlled particles create a perfect, smooth surface. This removes defects and improves the look of your product.

From Cost to Profit: Understanding Total Cost of Ownership (TCO)

This technical advantage brings direct financial benefits. The best way to measure a raw material’s value is not its purchase price, but its Total Cost of Ownership.

TCO = Initial Purchase Price + Operation & Maintenance Costs + Costs from Bad Products

Here’s how Mega Plast’s filler masterbatch is a Cost-Saving Solution that lowers your TCO:

- Lower Maintenance Costs: Less equipment damage means buying fewer spare parts and a longer life for your machines.

- Higher Productivity: Less downtime from filter blocks means more output per day and better use of your factory.

- Fewer Rejected Products: Consistent Quality leads to a stable final product, which reduces waste and saves money.

A local Indian product might have a lower price per kilo, but investing in Mega Plast’s masterbatch is an investment in your factory’s efficiency that brings great results.

Choose a Partner, Not Just a Supplier

In the fast-changing Indian nonwoven market, the winning company is not the one that buys the cheapest materials, but the one that operates most efficiently. Thinking about TCO instead of just the initial price is necessary for long-term profit and growth.

Mega Plast is more than a supplier; we are a technical partner with proven results. We provide an engineered solution that gives you better performance, stable production, and a provably lower Total Cost of Ownership.

Don’t just take our word for it. Let the data show you the difference.

Request Your Customized Performance Comparison and TCO Calculation Report Today.