Table of Contents

Introduction: Challenges in the PE Film Industry

CaCO3 Filler Masterbatch for PE Film plays a critical role in determining surface quality and production consistency. In the polyethylene (PE) film industry, even a small streak, black spot, or clogged filter can result in entire batches being rejected—leading to costly material losses and downtime.

But what happens when the root cause of these issues lies in the filler masterbatch itself? This is how a PE film manufacturer in Brazil overcame these challenges and restored production stability through Mega Plast’s comprehensive solution.

The Challenge: A Chain Reaction of Problems from Poor-Quality Filler

Our partner in Brazil reached out to Mega Plast in an urgent situation. Their production line faced continuous problems when using CaCO3 filler masterbatch from another supplier, creating a negative chain reaction:

🔴 Product Quality Issues:

The finished PE films showed dense streaks, black points, and color blotches, rendering them aesthetically unacceptable and unusable.

🔴 Reduced Production Efficiency:

Clogged mesh screens occurred frequently, forcing operators to repeatedly stop machines for cleaning. This drastically increased downtime, labor costs, and disrupted production schedules.

🔴 Increased Material Costs:

Defective batches had to be scrapped, wasting large amounts of raw materials and directly cutting into profits.

Recognizing the severity of the issue, the customer sent samples of their current filler masterbatch to Mega Plast for analysis and support.

Mega Plast’s Comprehensive Solution: Beyond Just Supplying Products

Upon receiving the request, Mega Plast initiated a professional, multi-dimensional approach, acting as a true solutions partner rather than just a supplier.

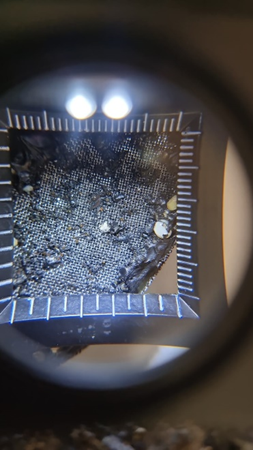

✅ In-Depth Analysis:

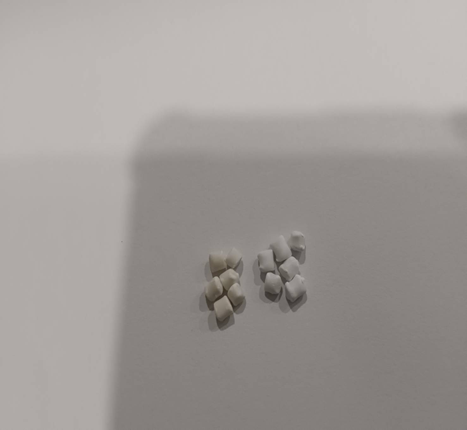

Our R&D team analyzed the competitor’s sample and quickly identified the problem. Visible black impurities were present within the filler granules. The pellets also lacked brightness, indicating low-grade CaCO3 powder.

✅ Premium Product Recommendation:

Mega Plast proposed a complete replacement: our high-grade CaCO3 filler masterbatch, produced using pure, high-brightness CaCO3 powder free from impurities. This new formulation was designed to eliminate filter clogging and ensure film consistency.

✅ Strict Quality Assurance:

To guarantee optimal performance, Mega Plast implements rigorous QA controls starting from raw CaCO3 powder selection, strictly preventing contamination risks during production.

✅ Operational Technical Support:

We understood residual impurities from old materials could remain in customer machinery. Mega Plast proactively guided them through an effective die-head cleaning process to remove all leftover contaminants and ensure smooth production.

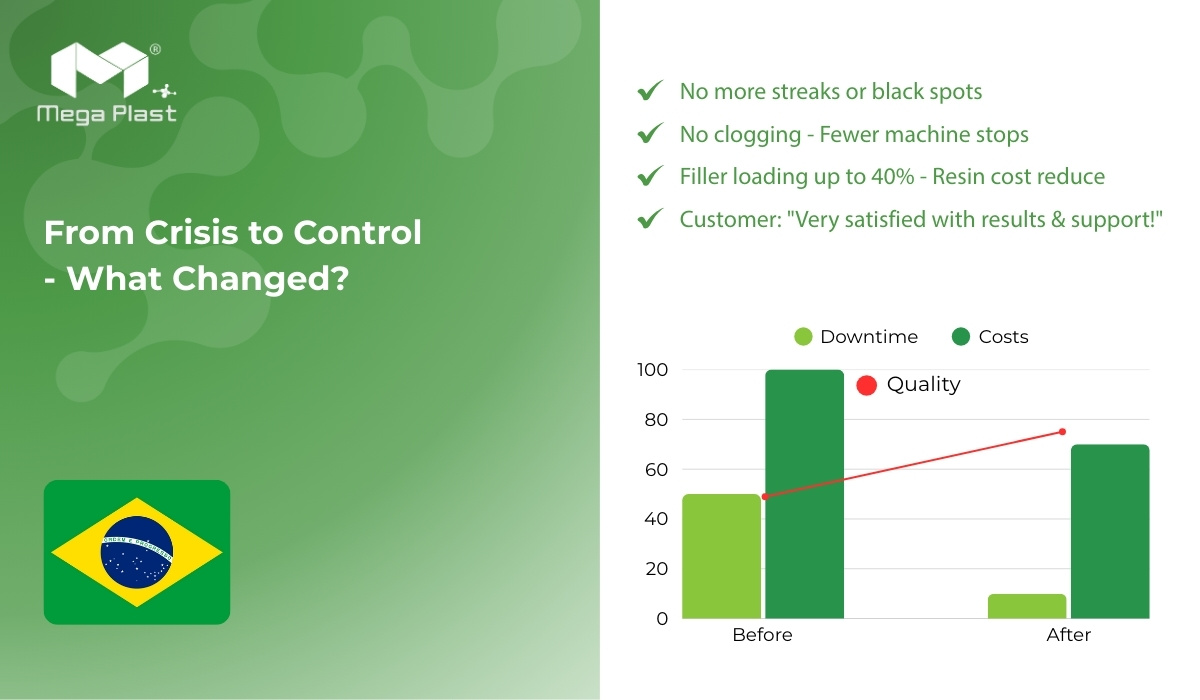

Breakthrough Results: From Crisis to Optimized Efficiency

Mega Plast’s comprehensive solution delivered impressive outcomes, transforming the customer’s production:

✔️ Flawless Film Quality:

Streaks, blotches, and black points were completely eliminated. Finished PE films had smooth, clear, and defect-free surfaces.

✔️ Optimized Production Efficiency:

With no more filter clogging or impurities, production efficiency increased significantly, reducing downtime and labor costs.

✔️ Significant Cost Savings:

Our high-quality filler masterbatch allowed loading rates up to 40% while maintaining superior product quality, dramatically cutting raw material costs.

✔️ Customer Satisfaction:

The Brazilian partner expressed the highest satisfaction with both Mega Plast’s product quality and our dedicated technical support.

Product Information: MEGA PLAST F261 CaCO3 Filler Masterbatch

- Product Name: CaCO3 Filler Masterbatch – F261

- Carrier Resin: Polyethylene (PE)

- Main Applications: PE blown film, packaging film, food wrap, agricultural film, shopping bags

- Technical Data Sheet: Download here

- Key Benefits:

✔️ Produced from pure, high-brightness CaCO3 powder

✔️ Free from impurities, no black spots

✔️ Superior dispersion, effectively prevents filter clogging

✔️ Ensures smooth, clear, consistent film surfaces

👉 Facing similar film production problems? Contact us today for a consultation and to request free samples.

Conclusion: Reinforcing Our Position as a Trusted Partner

Mega Plast’s proactive approach and premium products successfully resolved all of the customer’s production challenges. By improving film quality, reducing production costs, and enhancing operational efficiency, Mega Plast further strengthened its reputation as a reliable partner, providing “tailor-made” solutions for the PE film industry.

Explore our journey in Masterbatch field: Mega Plast – 21 Years of Leadership in Filler Masterbatch Market