Table of Contents

In the competitive landscape of plastic manufacturing, optimizing material costs without compromising product integrity is a constant challenge. For manufacturers involved in the production of oil jerry cans, increasing the filler loading rate is a proven strategy for a Cost-Saving Solution.

However, higher loading rates often lead to structural weaknesses if the Filler Masterbatch formulation is not perfectly matched to the production equipment.

This case study from a strategic partner in Southeast Asia illustrates how Mega Plast transforms technical challenges into operational success, ensuring high-performance results even at demanding loading rates.

1. The Challenge: Balancing High Loading Rates with Structural Integrity

The client, a prominent manufacturer of plastic oil jerry cans, aimed to achieve a 40% filler loading rate to maximize cost efficiency. To facilitate this trial, Mega Plast provided an initial 300kg free sample of our standard Filler Masterbatch grade B204.

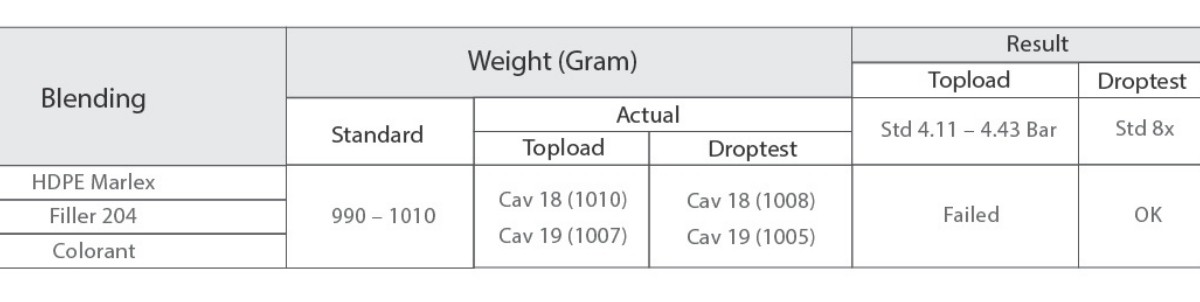

The initial trial yielded mixed technical results:

- Impact Resistance (Pass): The jerry cans successfully passed the Drop Test, surviving 20 consecutive drops without breakage. This demonstrated the excellent flexibility of our filler masterbatch.

- Structural Stiffness (Fail): The product failed the Top Load Test. Under vertical weight pressure (simulating warehouse stacking), the cans deformed and lost their shape.

The technical conclusion was clear: While the standard grade offered sufficient flexibility, it lacked the necessary stiffness to support the client’s specific container design at a 40% loading rate.

2. Strategic Intervention: Commitment to the 40% Target

In many industry scenarios, the standard advice for such a failure would be to reduce the loading rate. However, Mega Plast recognized that maintaining the 40% target was essential for the client’s commercial success.

Rather than compromising on the loading rate, our technical experts immediately flew to the client’s factory to solve the problem directly.

The 4-Step Technical Optimization Process:

- Data Analysis: We reviewed the test results to understand why the impact resistance was good but the stiffness was low.

- On-Site Audit: Mega Plast inspected the production line for oil jerry cans. We recorded specific machine parameters including temperature, blowing pressure, and cycle times.

- Sample Comparison: Our team collected samples of both the deformed cans and good cans to analyze the structural differences.

- Formulation Customization: We used this data to engineer a new tailored PE Filler Masterbatch grade called B204A. Our R&D team utilized lab-tested formulation methods to increase stiffness while maintaining impact strength.

3. The Result: Achieving Performance without Compromise

We conducted a second trial with the new customized grade Filler Masterbatch – B204A using the recorded machine settings. The results met all technical specifications:

- Top Load Success: The oil jerry cans remained rigid and maintained their structural integrity under stacking pressure, eliminating the deformation issue.

- Target Loading Rate Achieved: The client successfully maintained the 40% loading rate, preserving their projected cost savings.

- Operational Stability: The material processed smoothly, ensuring consistent cycle times and product quality.

Conclusion

A standard product specification may not always align with the unique variables of every production line. True value lies in a supplier’s ability to adapt and engineer materials that fit specific manufacturing requirements.

At Mega Plast, we provide more than just raw materials; we deliver Customized Filler Masterbatch Solutions backed by deep technical expertise and 21 years of experience. We are dedicated to ensuring your production targets are met.

Contact Mega Plast today to discuss a technical assessment for your Blow Molding production line.