Table of Contents

Filler Masterbatch for PP Nonwoven is a critical factor in ensuring high production efficiency and product quality. In the competitive PP nonwoven fabric industry, every percentage of cost savings and every hour of stable machine uptime is an advantage. A leading manufacturer in Colombia was facing critical production challenges that affected both their product quality and bottom line. Discover how Mega Plast delivered a customized solution that not only fixed the issue but also helped the client exceed their efficiency goals.

Client Introduction

- Company: A leading manufacturer of PP nonwoven bags

- Country: Colombia

- Industry: Manufacturing of PP nonwoven fabric for bags.

- Market: Domestic Colombian market and exports to other South American countries.

- Business Goal: To produce high-quality products to maintain a competitive edge in the market.

The Challenge: When Production Failures Hinder Growth Objectives

To optimize costs, the client was using a filler masterbatch from another supplier with a formula of 8% filler masterbatch and 92% virgin PP resin. However, they hit a major roadblock: the existing product only allowed a safe loading rate of 5-8%, far below their technical requirement of 15-30%.

When the production team attempted to increase the loading percentage, they immediately faced a series of severe issues:

- Dripping: The molten plastic constantly dripped from the extruder.

- Filament Sagging: The filaments sagged unevenly after leaving the extruder die.

- Fabric Thinning and Tearing: Increasing the CaCO3 Powder percentage caused the fabric to thin out, reducing its grammage and leading to frequent tears on the production line.

- Poor Tensile Strength: The final product failed to meet the technical specifications for machine-direction and cross-machine tensile strength.

These problems not only degraded the final product’s quality but also had significant consequences for the business:

- High Costs: The low loading rate meant that the cost-saving potential was not being realized.

- Reduced Productivity: A high scrap rate, combined with machine downtime for cleaning and restarting production, directly impacted overall output.

- Reputational Risk: Inconsistent product quality could damage the client’s reputation in the market.

Mega Plast’s Custom Solution: Filler Masterbatch for PP Nonwoven – N202A Grade

After realizing that their only prior solution was to reduce the filler loading—an economically inefficient option—the client decided to search for a new supplier and contacted Mega Plast.

Mega Plast’s R&D and Sales teams immediately took action. Instead of offering a standard product, we implemented a systematic analysis process:

- Sample Analysis: We tested the filler sample the client was currently using to identify the root cause of the failures.

- Research & Development: Drawing on our experience with other PP nonwoven fabric clients, the R&D team determined the problem was a compatibility issue between the filler and the client’s base resin.

- New Formulation: Mega Plast developed a custom formula for the N202A filler masterbatch, featuring two key differentiators:

- Adjusted CaCO3 Powder Content: The calcium carbonate content was optimized to improve dispersion.

- High MFI PP Carrier Resin: This carrier resin offered better compatibility with the client’s plastic, improving the melt flow of the mixture and resolving the dripping and sagging issues.

Within just two weeks, a complete solution was developed, and trial samples were sent to the client.

The Results: Exceeding Expectations

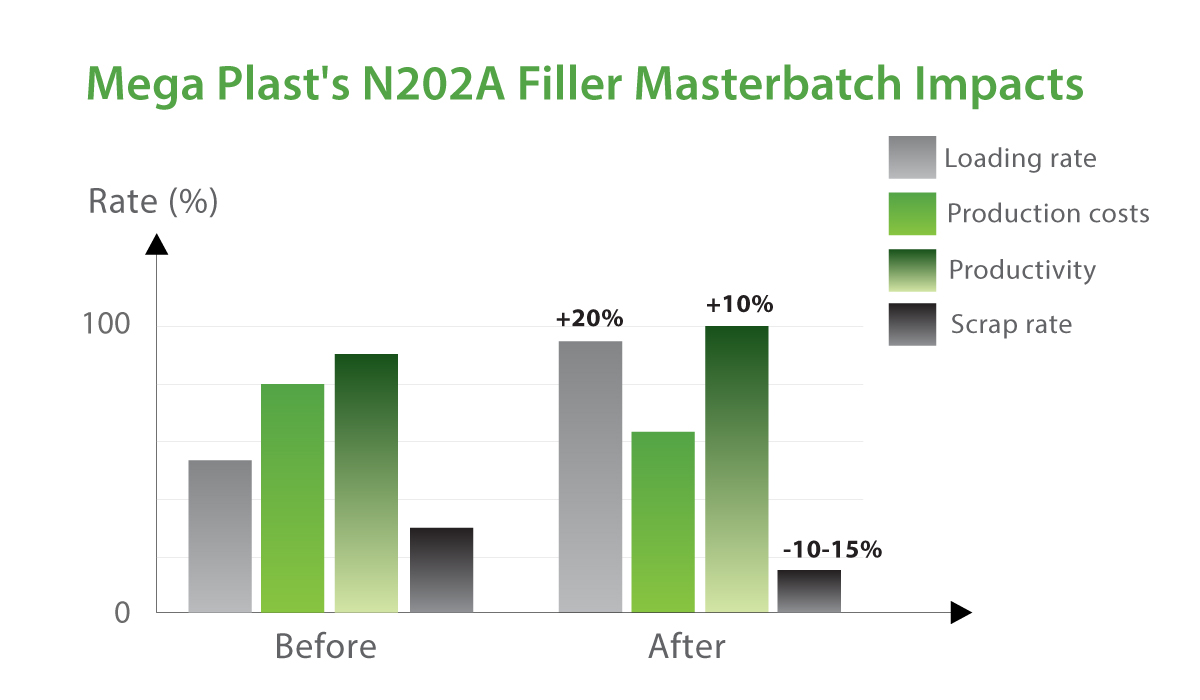

Mega Plast’s N202A Filler Masterbatch was not just a replacement; it was a comprehensive upgrade for the client’s entire production process.

- Technical Success: The dripping and fabric-tearing issues were eliminated. More importantly, the client was able to increase the filler loading rate to 20% without any complications.

- Cost & Production Efficiency:

- An additional 15% in production costs was saved thanks to the higher loading rate.

- Productivity increased by 10% due to reduced downtime and stable operations.

- The scrap rate was significantly reduced, optimizing raw material usage.

- Business Impact: This solution directly helped the client achieve their core business objective: reducing production costs while maintaining high quality.

Client Feedback and Future Partnership

The client expressed deep satisfaction, noting that Mega Plast provided not only a “good price and high-quality product” but also “excellent service”. The quality of the final bags also improved, delivering better value to their end consumers.

Following this success, the client has decided to place regular orders and transition their entire volume from the previous supplier to Mega Plast. For our part, Mega Plast is committed to continuing research and improving the formula to help the client achieve even higher loading rates in the future.

This case study is a clear testament to Mega Plast’s philosophy: we don’t just sell products; we provide solutions. By listening, analyzing, and customizing, we help our clients turn challenges into growth opportunities.

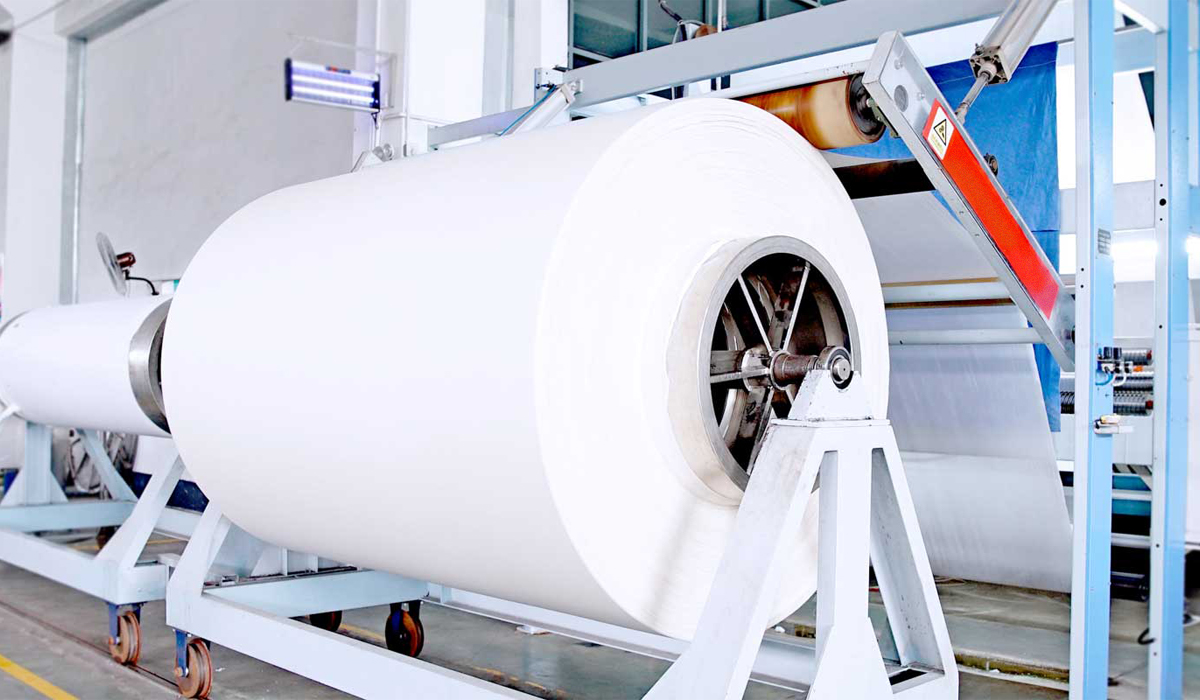

Discover Inside the Mega Plast Factory: Where Cutting-Edge Technology Meets Strict Quality Control