Table of Contents

Filler Masterbatch for PP Woven is the hidden driver behind major gains in speed and cost savings in the woven bag industry. In today’s competitive market, PP woven producers constantly seek ways to boost output and reduce raw material costs—without compromising durability or quality.

This was exactly the challenge faced by a leading PP woven bag manufacturer in Guatemala. Their goal? Maintain high-speed production and eliminate unnecessary additives—without inflating costs. With the support of Mega Plast’s W202 filler masterbatch, they turned this challenge into a success story.

The Background: A Market Leader’s Goal for Optimization

Our client is a major manufacturer in Guatemala, specializing in high-quality PP woven bags for essential agricultural products like sugar, coffee, and potatoes. With a business strategy centered on high-speed production to maximize efficiency and maintain competitive pricing, they are constantly seeking the most advanced material solutions.

When Mega Plast initiated contact, we discovered they were facing a significant bottleneck in their production process.

The Challenge: The Hidden Cost of Speed

The core of the client’s problem lay in their existing material formulation. They were using a filler masterbatch from India, but it failed to perform when their Starlinger machines were pushed to high speeds (420-480 m/min).

Here were their initial production parameters:

Machine: Starlinger

PP Resin: PP NSY144G

Target Speed: 420-480 m/min

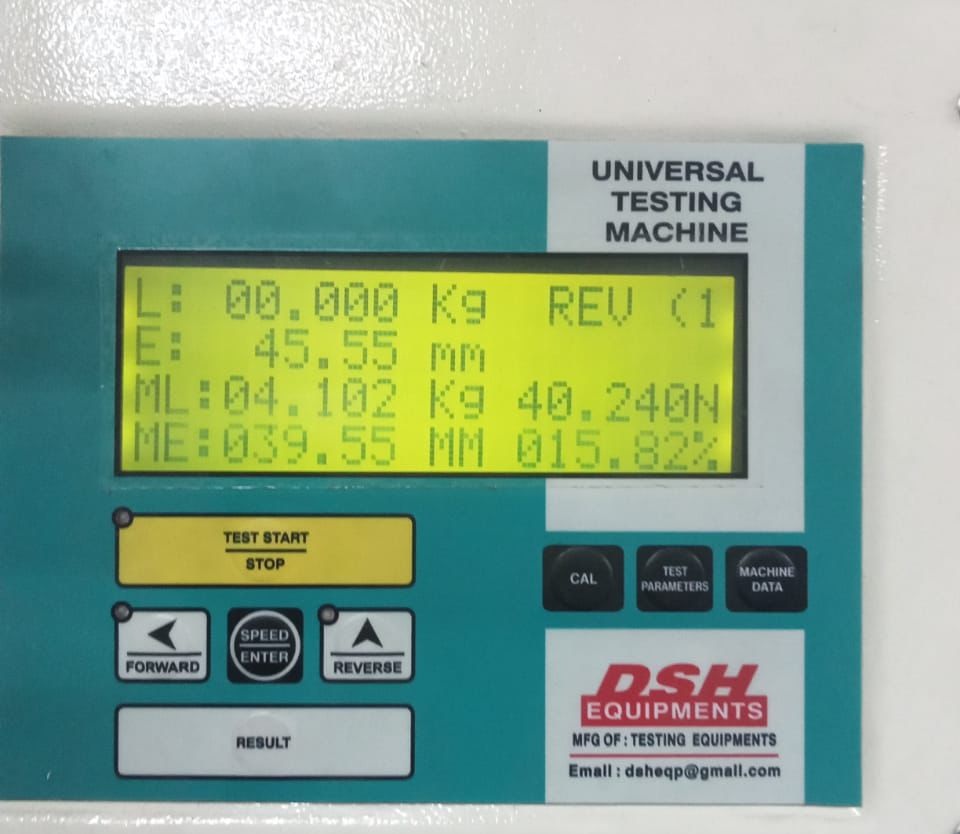

Technical Specs: Tensile Strength (4-5 KGF), Elongation (23%), Denier (750)

Heat Temperature: 230-280°C

The core problem was their filler masterbatch from India. It couldn’t handle the high speeds alone. To prevent issues, they were forced into an expensive workaround: adding 5% of a separate toughness additive.

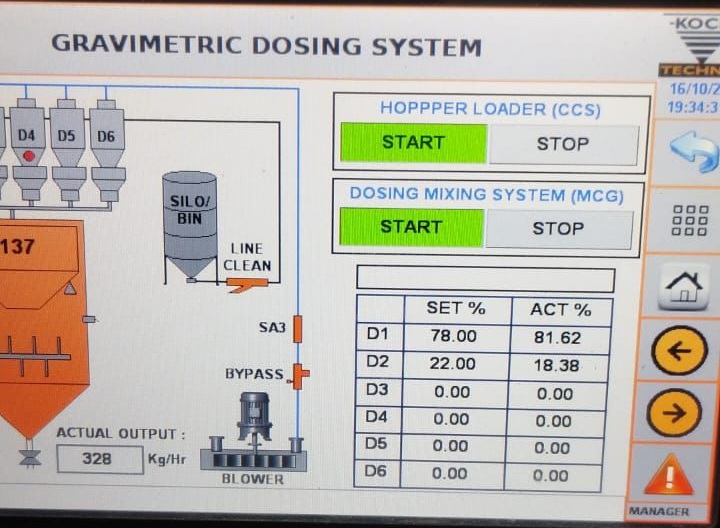

- Old Formula: PP Resin + 18% Indian Filler + 5% Toughness Additive

The problem? This toughness additive was extremely expensive, costing over $1,500 per ton. This directly inflated their production costs, eroded their competitive edge, and contradicted their primary goal of cost optimization. They were caught between the need for speed and the pressure to control expenses.

The Mega Plast Solution: Filler Masterbatch for PP Woven with W202 “All-in-One” Formula

After a thorough analysis of the client’s technical parameters and processes, Mega Plast’s R&D team engineered a breakthrough solution: our W202 Filler Masterbatch.

PP Filler Masterbatch for PP Woven – W202

What makes W202 different? This isn’t just a standard filler. W202 is an “all-in-one” product, expertly formulated with the necessary strengthening additives already integrated.

We proposed a new, much simpler, and more effective formula:

- New Formula: PP Resin + 25% Mega Plast W202

This solution delivered a dual benefit:

- It eliminated the need for the expensive, third-party toughness additive.

- It allowed for a higher filler loading rate of 25%, saving a significant amount of virgin PP resin.

The client now needed only one masterbatch to solve two major problems, ensuring product durability at high speeds while radically optimizing costs.

The Outstanding Results: The Numbers Speak for Themselves

After a year of trials and receiving positive feedback from end-users in the US market, the client fully committed to Mega Plast’s solution. The results were impressive and consistently stable.

- Production Performance:

- Machine speed stabilized at a consistent 450 m/min.

- Flawless tape quality with no water carry-over or dust issues.

- Guaranteed Technical Specs:

- Tensile Strength: Achieved 4.5 KGF

- Denier: 750

- Elongation: 23%

- The Bottom Line—Clear Economic Benefits:

- A direct saving of $75 per ton of the final product!

This was a massive cost reduction that helped the client achieve their core business objective: producing high-quality goods at the most competitive price point.

Long-Term Impact and Future Partnership

Mega Plast’s solution did more than just solve a technical problem; it created a positive ripple effect across their entire business. By lowering their production costs, they strengthened their market position and enhanced their reputation with their partners.

This success has paved the way for a long-term strategic partnership. The client plans to continue collaborating with Mega Plast on new product development, ensuring they remain at the forefront of innovation and market leadership.

This story from our Guatemalan partner is clear proof: with the right partner and the right material solution, any production challenge can be overcome. Are you facing similar issues in your manufacturing process?

Contact Mega Plast today for a consultation and a free sample. We are ready to help you find your optimal solution!