Table of Contents

The Reality of the European Plastics Market

K 2025 Plastic is where Mega Plast tackles Europe’s biggest manufacturing challenges head-on. The European plastics market is under intense pressure, caught between the need to innovate and the demand to control costs. This creates daily challenges on the factory floor: how do you increase efficiency without risking quality? How do you secure your supply chain in a volatile global market? And how do you find a reliable partner you can truly trust?

At K 2025 Plastic, Mega Plast isn’t just an exhibitor. We’re bringing proven, data-backed solutions to the three most urgent issues manufacturers face. We invite you to a conversation about performance, reliability, and real cost savings.

Part 1: The Technical Challenge

In the competitive PP Woven sector, speed is everything. Manufacturers need their lines to run at high speeds, often from 450 MPM to 550 MPM, to stay profitable. However, standard CaCO3 Filler Masterbatch products often fail under this intense pressure.

This failure isn’t a small issue. It leads to frequent tape breaking, which means costly downtime. It creates dust, which wears down expensive machinery. It results in poor end-product quality, increasing your reject rate and damaging your reputation with customers. The pressure to run faster often leads to higher operational costs, completely wiping out any savings from a “cheaper” material.

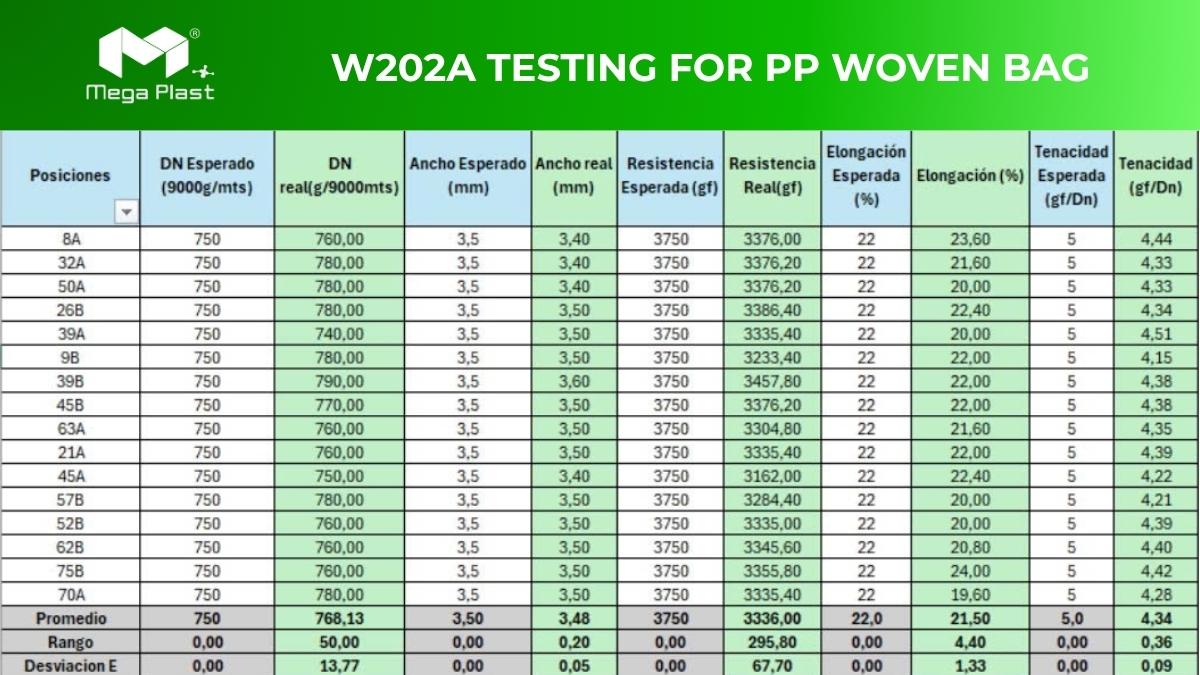

One leading PP Woven bag manufacturer in Colombia was facing this exact challenge. Operating in a highly competitive market, they struggled to balance speed, quality, and cost. Their high-speed machinery was unforgiving, and using lower-quality filler was directly increasing production costs due to defects and damaging their reputation. They were skeptical that a supplier from Vietnam could meet their demanding technical standards. But instead of offering a standard product, Mega Plast proposed a 6-month collaborative R&D project. Our technical team analyzed their machine parameters and production goals, listening carefully and co-engineering a solution with their in-house team.

The outcome was W202A – a filler masterbatch custom-designed for high-speed lines. After a two-month trial, the impact was clear: the client could maintain top machine speeds without tape breaking, increasing overall productivity. Even better, the high quality of W202A allowed them to raise their filler loading rate, replacing more virgin PP resin and reducing production costs by 20%. This success turned a technical barrier into a competitive edge, and the client now places monthly orders with Mega Plast.

This is the power of a true R&D partner.

Click to watch: How Our Filler Masterbatch N202A Transformed PP Nonwoven Production in Colombia

Part 2: The Supply Chain Challenge

Recent global events have exposed just how fragile international supply chains can be. For European producers and global traders alike, a delay from an overseas supplier isn’t just a minor disruption – it can bring an entire factory to a halt. This was especially true for a major trading company in Ghana that was preparing to expand into a new product category: White Masterbatch. Used in PE Blown Film, PE Extrusion, PE Low Molding, and PP Injection applications, the product had high market demand but fulfilling that demand hinged entirely on finding a reliable and scalable supplier.

The pressure was immense. The Ghanaian trader needed to place an initial order of two full containers—an investment that, if delayed or mishandled, could damage their credibility across their entire customer network. They weren’t just asking for a product—they were asking for stability, speed, and the ability to respond to market opportunity without hesitation. In today’s volatile climate, the real question for suppliers isn’t “Can you ship?” but “Can you guarantee delivery, even in a crisis?”

Mega Plast rose to the challenge with confidence, powered by our vertically integrated system and large production capacity. Because we own our CaCO3 sources and control every step of the production process, we were able to guarantee not just quality but timely delivery. The entire two-container order was produced and shipped on schedule, giving our Ghanaian partner the credibility and inventory needed to seize a new market opportunity. Our supply chain wasn’t just resilient—it was a launchpad for their business expansion.

Part 3: The Supplier Quality & Reliability Challenge

Choosing a new supplier from a distant country always carries risk. Samples may look perfect, but what about the 10th or 20th container? For a plastic bag manufacturer in Yemen, this risk was magnified by extreme local conditions – civil war, high sea freight costs, and even double taxation. In such a volatile market, they didn’t just need affordable raw materials – they needed a dependable partner who understood how to navigate complexity without mistakes.

Inconsistent quality from a supplier is a silent killer of profitability. One bad batch can compromise your entire product line and generate waves of customer complaints. Worse still, in fragile markets with unstable logistics and strict regulations, even a small error—like incorrect paperwork or poor freight planning—can delay shipments for weeks and cripple your operations. Reliability and real-world experience aren’t optional; they’re mission-critical.

Mega Plast approached the partnership with both technical precision and logistical expertise. Our sales and R&D teams worked closely with the client. We didn’t just offer a product; we offered our expertise. We developed a custom PE film grade, F281, based on their specific needs (film thickness 20-30 microns, loading rate 10-15%) to save them costs. Crucially, our logistics team planned the shipment meticulously to navigate the challenging route.

In the end, We have successfully and consistently delivered our custom-made product to Yemen. This proved we are a partner who can be trusted to deliver quality and reliability even in the most volatile and high-risk environments, significantly “de-risking” the client’s operation.

Let’s Solve Your Challenges Together

Technical barriers, supply chain disruptions, and quality risks are not challenges you have to face alone. They are problems waiting for the right solution from the right partner.

We invite you to our booth at K 2025. Bring your toughest challenges. Let’s have a data-driven conversation about how Mega Plast can become your most reliable partner for growth and profitability.

Find us at: Hall 7, Level 2 – Booth B25

Date: October 8-15, 2025 | Düsseldorf, Germany