Table of Contents

Introduction: The Woven Packaging Landscape in Indonesia

As an agriculture-driven economy, Indonesia relies heavily on its woven bag industry. PP woven bags are widely used to package rice, grains, fertilizers, and countless other agricultural commodities.

In this competitive market, manufacturers are under constant pressure to produce high-quality bags that withstand harsh conditions during transportation, handling, and storage – all while optimizing production costs.

This is the story of how one leading Indonesian manufacturer faced this challenge and overcame it with Mega Plast’s tailored solution.

Challenges: Weak Bag Strength – A Major Risk for Agricultural Products

Our partner in Indonesia was facing a critical issue: the tenacity of their PP woven bags decreased significantly after adding CaCO3 Filler Masterbatch from their existing supplier.

As a result:

- Finished bags had poor strength and tore easily under load

- They were unsuitable for packaging heavy agricultural products

- Product loss and damage affected customer trust and brand reputation

- Inconsistent quality between batches created production instability and difficulties in controlling output standards

They needed a solution that would not only solve the strength issue but also ensure stability and cost efficiency.

Solution: Superior Quality at Competitive Pricing from Mega Plast

Upon receiving the customer’s inquiry, Mega Plast’s technical team quickly analyzed the situation. With over 21 years of industry experience and deep expertise in PP woven bag applications, we identified the root cause: the formula and quality of the masterbatch they were using.

Mega Plast’s Comprehensive Solution

✅ Specialized Product:

We introduced CaCO3 Filler Masterbatch Grade W262, designed by our R&D experts to enhance the tenacity and durability of PP woven bag yarns.

✅ Advanced Technology:

W262 is produced on state-of-the-art manufacturing lines, ensuring excellent dispersion of calcium carbonate in the polymer matrix. This eliminates weak points along the yarn, resulting in uniform strength across the entire product.

✅ Consistent Quality:

We guarantee batch-to-batch consistency, resolving the variability issue they faced with their previous supplier.

✅ Competitive Pricing:

Most importantly, Mega Plast offered this superior solution at the same price as the low-quality product they had been using.

Get to know more about our 21 years journey: Mega Plast: 21 Years of Leadership in Filler Masterbatch Market

Result: Impressive Improvements Backed by Numbers

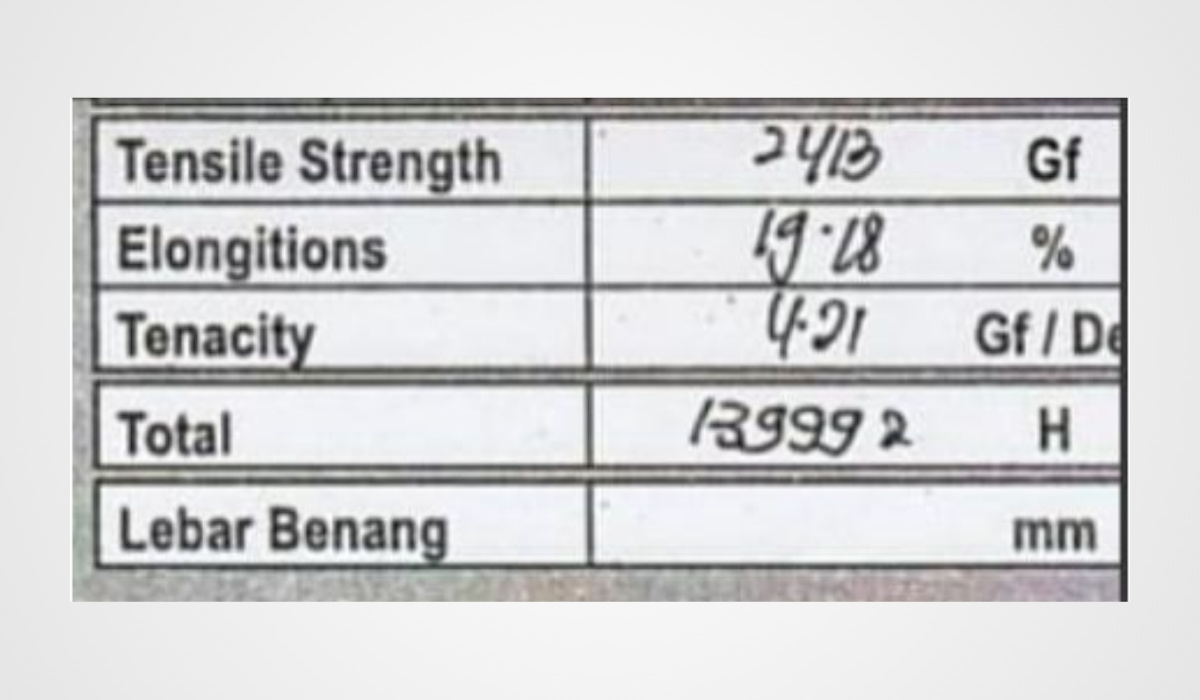

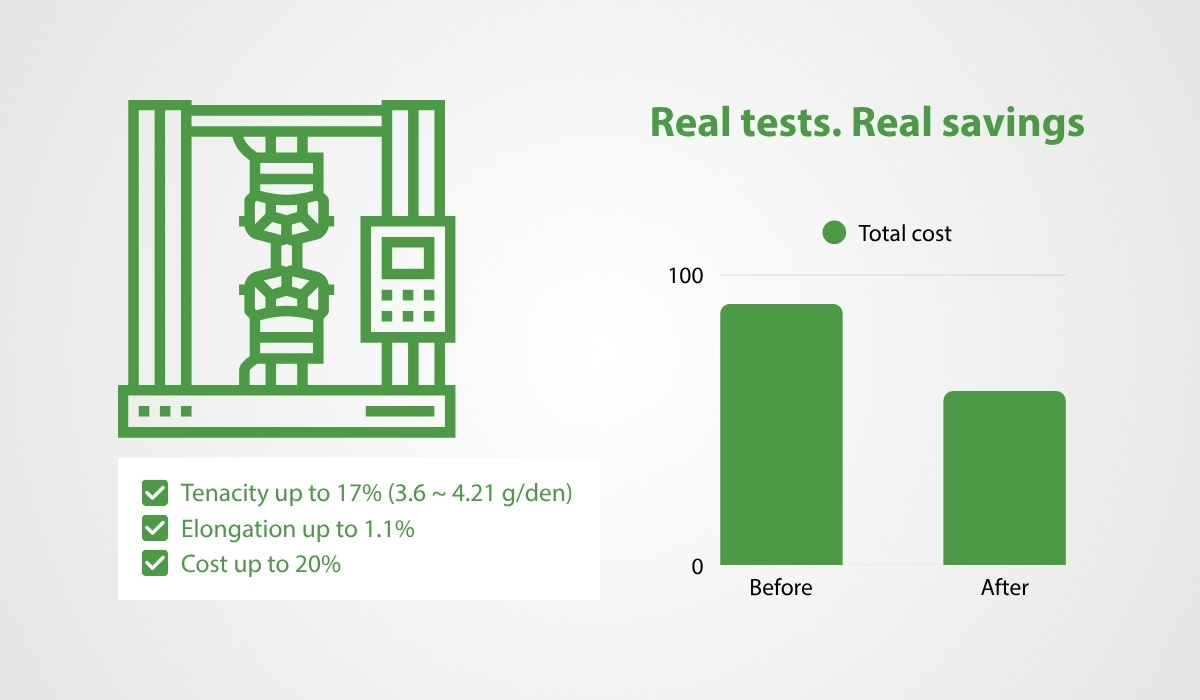

After switching to Mega Plast’s W262 filler masterbatch, the manufacturer recorded remarkable results:

✔️ Significant Strength Increase:

- Tenacity increased from 3.6 g/denier to 4.21 g/denier (~17% improvement)

- Elongation improved from 18.05% to 19.18%

This ensured the bags could carry heavy agricultural products without tearing, enhancing durability and customer satisfaction.

✔️ Production Cost Savings up to 20%:

Thanks to W262’s excellent compatibility and stable quality, the manufacturer could increase filler loading rates while maintaining strength, significantly reducing raw material costs.

✔️ Higher Production Efficiency:

Consistent product quality minimized production delays and reduced defect rates, ensuring that production lines ran smoothly and efficiently.

Product Information: MEGA PLAST CaCO3 Filler Masterbatch W262

- Product Name: CaCO3 Filler Masterbatch – W262

- Carrier Resin: Polypropylene (PP)

- Main Applications: PP woven bags, PP non-woven fabrics

- Technical Data Sheet: Download here

- Key Benefits:

- Enhances tenacity and tensile strength

- Excellent dispersion for smooth yarn surface without streaks

- High whiteness and opacity

- Superior compatibility with PP resin and other additives

- Enhances tenacity and tensile strength

👉 Want to learn more about W262?

Contact us today to request free samples and technical consultation.

Conclusion: Your Reliable Partner for Success

This Indonesian manufacturer’s success story is clear proof of Mega Plast’s commitment: We don’t just provide products – we deliver complete solutions.

By offering a tailored formula at competitive pricing, Mega Plast helped the customer resolve their quality issue, achieve stronger and more durable products, and optimize production costs. Combined with our reliable supply chain, we ensured uninterrupted production without delays.

At Mega Plast, our customers’ success is our success. We are proud to be the strategic partner of choice for plastics manufacturers on their journey towards sustainable growth.