The term ‘filler masterbatch’ might seem esoteric to those outside the plastic manufacturing sector. To untangle the meaning, one must first understand the concept of a masterbatch.

A masterbatch is a solid or liquid additive used for coloring or enhancing the properties of polymers. It’s a concentrated mixture of pigments, dyes, and additives encapsulated during a heat process into a carrier resin which is cooled and cut into a granular shape.

Filler masterbatch, under this broad category, is used to improve the physical attributes of the plastic without dramatically changing its color or end application properties. The main component—filler—typically comprises inorganic materials like calcium carbonate, talc, or other minerals. These materials are chosen for their ability to deliver properties such as stiffness, durability, or UV resistance.

The demand for filler masterbatch across different regions is influenced by various factors, including industrial growth, environmental policies, consumer preferences, and local market needs. These factors, in turn, affect the types of polymeric matrices preferred in filler masterbatch formulations.

The plastic industry is a synapse in the world economy, infiltrating almost every segment with its ubiquitous presence. Masterbatches, in particular, play a critical role in enhancing the aesthetic and functional properties of plastics. Amongst various types of masterbatches, the demand for filler masterbatches has been scaling new heights globally.

This brings forth an interesting conundrum—how is filler masterbatch shaping up in diverse global markets?

From the towering skyscrapers of urban cityscapes to the tranquil rural homes, from the sophisticated electronics circuits to the rugged automotive parts, filler masterbatch is quietly transforming the landscape. It might go unnoticed, but its impact is unmistakable.

This deep-dive blog post journeys through the global demand for filler masterbatch, meandering across the unique trends and preferences in different regions and industries, to provide you with a comprehensive understanding of the plastic industry’s versatile chameleon.

The Driving Forces of Filler Masterbatch Demand

The burgeoning demand for filler masterbatch is not a happy coincidence. It is the result of several macroeconomic, technological, and environmental factors that converge to make filler masterbatch an indispensable component in various applications.

Eco-friendly Initiatives

Environmental regulations and a broader global push toward sustainability are steering the demand for filler masterbatch. By enabling manufacturers to use less virgin resin, filler masterbatch supports the circular economy, reducing waste, and energy consumption. Its role in lightweighting, a process to reduce the amount of plastic in products, is also driving its increasing adoption.

Cost-effectiveness

In a landscape where every cent matters, filler masterbatch offers a cost-effective solution. By reducing the amount of expensive virgin polymers, manufacturers can lower production costs significantly. This is particularly appealing to high-volume production lines where minor savings per unit can translate into substantial overall benefit.

Customization and Adaptability

Industries are not monolithic; they’re composed of diverse players with unique requirements. Filler masterbatch, with its customizable nature, allows for the fine-tuning of plastic properties. From a mechanical characteristic like increasing the tensile strength to an aesthetic requirement like reducing gloss, filler masterbatch caters to a spectrum of needs.

The Regional Tale of Filler Masterbatch

Every region has a narrative—unique in its language, flavor, and in our context, in its utilization of filler masterbatch. Understanding these regional nuances is crucial for suppliers and manufacturers looking to tap into international markets. Here, we dissect the demand for filler masterbatch in four key regions—Asia, Europe, North America, and Latin America.

Asia’s Insatiable Appetite

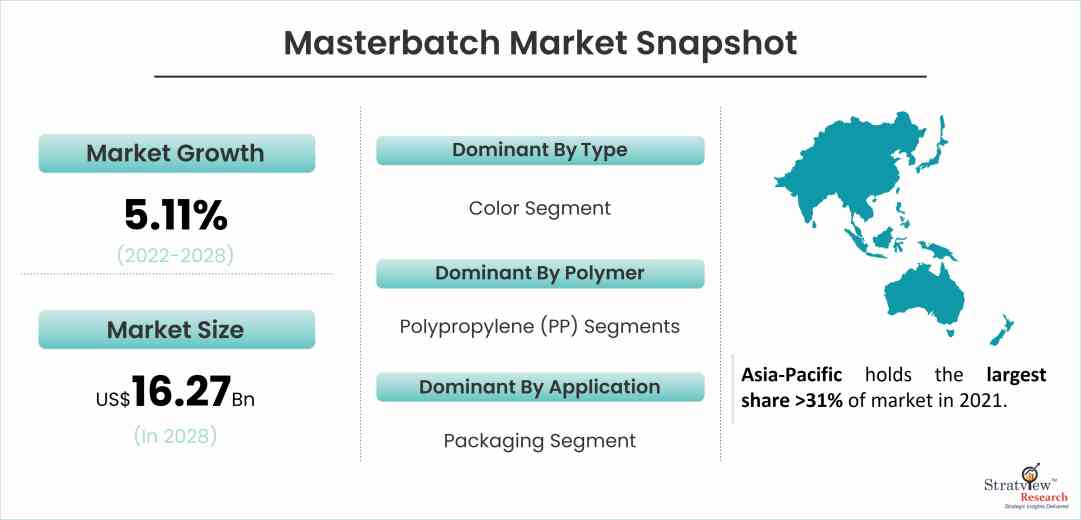

Asia-Pacific has been the frontrunner in global masterbatch and plastic production for several years, and the demand for filler masterbatch has been increasing in tandem. Countries like China, India, and South Korea boast thriving plastic industries, with each market exhibiting distinct preferences.

China’s enormous manufacturing sector, which caters to both domestic and international markets, relies heavily on filler masterbatch for its sheer volume efficiency. India, on the other hand, is experiencing a surge in the construction, automotive, and packaging sectors, all of which are fueling a robust demand for filler masterbatch.

The spike in e-commerce, especially in Southeast Asia, has driven up the need for packaging materials that leverage the benefits of filler masterbatch, such as the durability of UV-resistance.

High Demand for PE and PP Matrices:

In the APAC region, particularly in rapidly developing countries like China, India, and Vietnam, there’s a significant demand for polyethylene (PE) and polypropylene (PP) based filler masterbatches. This demand is driven by the booming packaging industry, agricultural applications, and consumer goods manufacturing.

The region’s focus on cost-effective solutions for mass-produced items makes PE and PP attractive due to their balance of performance and affordability. The expansion of the middle class in these countries also fuels the demand for consumer products that rely on these materials.

The European Narrative

The European Union’s stringent environmental regulations have turned out to be a significant driver of filler masterbatch demand. The EU’s Circular Economy Action Plan and the Single-Use Plastics Directive are pushing manufacturers to adopt more sustainable practices. This has led to a surge in demand for materials that contain filler masterbatch, as it aligns with the EU’s vision for a greener industry.

However, Europe isn’t just about regulations; it’s also dictated by consumer preferences. With an increasingly eco-conscious market, products that tout sustainability as a feature are more likely to find favor. The automotive and consumer goods sectors, in particular, are increasingly adopting filler masterbatch to adhere to these dual requirements of regulation and consumption patterns.

Preference for High-Performance and Sustainable Matrices:

In more developed markets such as North America and Europe, there’s a growing demand for filler masterbatches with polymeric matrices that offer high performance and sustainability. This includes polymers like PET (Polyethylene Terephthalate) for packaging applications due to its excellent barrier properties and recyclability.

Additionally, environmental regulations and consumer preferences for sustainable products have led to increased interest in biodegradable and bio-based polymers as matrices in filler masterbatch formulations.

North America’s Innovative Culture

The United States and Canada have a reputation for innovation and flexibility in their manufacturing practices. This has translated into a strong demand for filler masterbatch, particularly across the automotive, construction, and packaging segments. The shale gas revolution has also made raw materials cheaper, encouraging the adoption of filler masterbatch as a cost-effective measure.

The emphasis on sustainable practices, though not as rigorous as in Europe, is growing in North America. The circular economy is driving the need for filler masterbatch in recycling and packaging materials. With a consumer base that’s becoming increasingly aware and demanding, North American manufacturers are under pressure to adopt more environmentally friendly practices, making filler masterbatch an attractive solution.

Latin America’s Ascension

Latin America might not have the powerhouse economies of China or the U.S., but it offers untapped potential for filler masterbatch manufacturers. Brazil, in particular, with its robust automotive and agricultural sectors, presents a significant market for filler masterbatch. The need for filler masterbatch in the film and packaging industry is also on a consistent upswing, fueled by the region’s commercial and retail growth.

However, the demand in Latin America is not just about industrial growth; it’s also influenced by the region’s unique climatic and environmental conditions. The UV-resistance property, for instance, is highly sought-after in the plastics used in agriculture, where sunlight can be intense. It’s a testament to how filler masterbatch can cater to both industrial and geographical specifics.

Versatility and Cost-Effectiveness: PE and PP Matrices:

Latin American countries exhibit a preference for versatile and cost-effective solutions, with PE and PP-based filler masterbatches leading the demand. These materials support a wide range of applications, from agricultural films to packaging and household items, catering to the region’s diverse manufacturing needs.

Middle East and Africa (MEA)

Focus on Durability: PVC and HDPE Matrices:

The construction and infrastructure sectors dominate the filler masterbatch market in the MEA region. Polyvinyl Chloride (PVC) and High-Density Polyethylene (HDPE) are commonly used matrices due to their durability, resistance to environmental factors, and suitability for pipes, fittings, and construction materials.

Demand Influences on Polymeric Matrix Selection:

- Industrial Growth: Rapid industrialization in regions like APAC increases the demand for general-purpose polymers like PE and PP in filler masterbatches, supporting a wide range of applications.

- Environmental Policies: Stricter environmental regulations in Europe and North America drive the demand for sustainable polymeric matrices, including bio-based polymers and recyclable materials like PET.

- Consumer Preferences: Growing consumer awareness around sustainability and product safety influences the demand for eco-friendly and food-grade polymers in filler masterbatches.

- Economic Factors: Cost sensitivity in regions like APAC and Latin America prioritizes the use of affordable polymeric matrices that do not compromise on product quality.

The selection of polymeric matrices in filler masterbatch formulations is closely tied to regional demands, reflecting local market needs, environmental concerns, and industrial applications. As global trends shift towards sustainability and high-performance materials, the filler masterbatch industry adapts by exploring innovative polymeric matrices that meet these evolving requirements.

Manufacturers and suppliers must stay attuned to these regional preferences and emerging global trends to cater effectively to the diverse and changing market landscape.

Continue your journey into the world of masterbatch by reading ‘Choosing the Right Filler Masterbatch: A Guide for Manufacturers’.Click here to read more and expand your understanding

Vertical and Horizontal Expansion of Masterbatch Utilization

Masterbatches are finding applications not just in the traditional segments of plastics—like packaging, automotive, and construction—but are also penetrating newer areas, leading to vertical and horizontal expansion.

The Traditional Segments

In the packaging industry, filler masterbatch is used to improve the mechanical properties of plastic films, maximizing the product’s shelf life and sustainability. In automotive, it enhances the durability and finish of interior and exterior components. And in construction, it boosts the UV-resistance and thermal stability of plastic materials used.

Expanding Horizons

The agricultural sector is a burgeoning market for filler masterbatch. In an era where food security is a global concern, technologies like greenhouse films and drip irrigation, both of which rely on plastics with the support of filler masterbatch, are becoming critical. Similarly, medical equipment manufacturing relies on the properties of plastic, with filler masterbatch ensuring that these are safe, durable, and color-coded for differentiations.

The Path Forward for Filler Masterbatch

The future of filler masterbatch is as diverse and dynamic as the markets it serves. A confluence of sustainability, innovation, and global economic shifts is paving the way for a material that’s not just a supporting act but an indispensable partner in the plastics industry.

Sustainable Innovation

The quest for sustainability is an enduring trail that the plastics industry is navigating with fervor. Sustainable filler masterbatch formulations that use bio-based and recycled materials are gaining traction. These formulations are not just ‘greener’ but also, in many cases, can enhance the performance of plastics.

Circular Economy

The principles of the circular economy are becoming ingrained in manufacturing practices worldwide. The plastic industry, with its focus on recycling and reusability, will rely on filler masterbatch to create materials that can be repurposed without loss of quality or properties.

Consumer Awareness

A more informed consumer base that’s acutely aware of the environmental impact of their purchases will continue to exert pressure on businesses to offer sustainable and responsible products. This trend will influence the design and usage of filler masterbatch, as it’s at the core of the movement toward environmentally friendly plastics.

In Closing

The story of filler masterbatch is one of versatility and growth. From its humble origins as a cost-effective additive, it has evolved into a critical enabler for diverse industries. Its role in the context of global trends such as sustainability, innovation, and digitalization is pivotal, underscoring the demand for a material that’s as adaptable as the plastics it enhances.

We encourage you to continue the conversation. Share your thoughts, experiences, and insights in the comments section below. The exchange of knowledge and ideas is essential if we are to collectively unlock the potential of filler masterbatch technology and drive the industry forward.

Whether you’re looking for a reliable supplier, interested in exploring our product range, or simply wish to learn more about our cutting-edge manufacturing processes, our team is ready to assist you. Contact us today to schedule a visit or consultation, and let’s explore how Megaplast can elevate your business to new heights. Your partnership in innovation starts here.

Pingback: The Alchemy of Manufacturing Process - Types of Polymeric Matrices of Filler masterbatch